The scattering setup was designed with a focus on hierarchical, wood-based materials; for example, the WAXS detector allows monitoring diffraction from cellulose fibrils/fibers in all directions of the scattering plane, which is instrumental for scanning SWAXS mapping of cellulose fibril orientation. Selected technical details are provided below.

Detectors

ForMAX is equipped with two state-of-the-art hybrid pixel detectors: a Dectris EIGER2 X 4M SAXS detector and a custom-designed X-Spectrum Lambda 3M WAXS detector.

| Detector | EIGER2 X 4M | Lambda 3M “windmill” |

|---|---|---|

| Usage | SAXS | WAXS |

| Number of pixels | 4M | 3M |

| Sensor size (h x v) | 2068×2162 pixels | 4x512x1536 pixels |

| Pixel size (h x v) | 75×75 µm2 | 55×55 µm2 |

| Maximum frame rate | 500 Hz | 1 kHz |

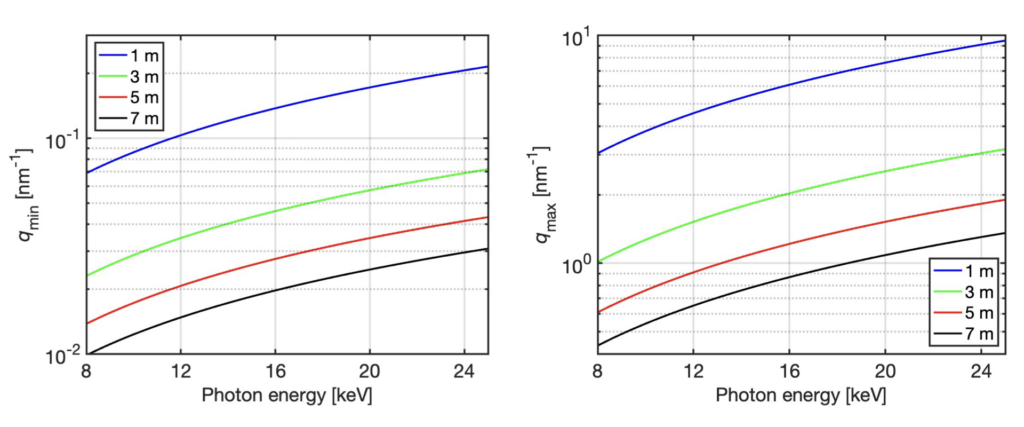

The SAXS detector is placed on a motorized XYZ trolley inside the SAXS flight tube and can be placed approximately 810 – 7600 mm downstream of the nominal sample position. The figures below show the smallest and largest scattering vector moduli versus x-ray energy for selected sample-to-detector distances (SDD), assuming the x-ray beam impinges in the center of the detector.

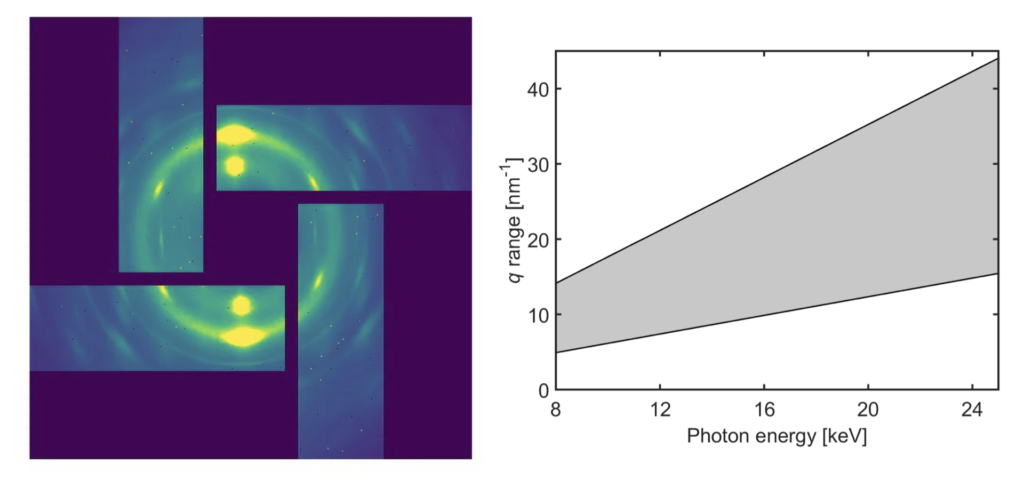

The WAXS detector is mounted on an evacuated nose cone of the flight tube and the four modules of the WAXS detector have a “windmill” geometry with a hole in the center, to pass through the direct beam and the SAXS signal (see image below). It allows WAXS data collection at scattering angles 2θ=7-20 degrees, in all directions. See table below for details of the detectors.

Sample manipulation

ForMAX offers a modular 7-axis stack of sample stages from Huber for SWAXS experiments. From bottom to top:

- 2-circle segment (pitch, roll), model 5203.30 (+/- 13 and +/- 12 degrees range for lower and upper axis, respectively)

- vertical stage, model 5103.C30 (+/- 10 mm)

- 2-axis horizontal stage, model 5102.25 (+/- 25 mm translation range for each axis)

- custom large-range pitch stage, model 5202.80 (+/- 45 degrees)

- yaw stage, model 408

- either a manual 5-axis goniometer head 1002/1005 or an optical breadboard (M6 25×25 mm centred hole pattern) can be mounted on top

- optional PMMA pins for sample mounting (local contact can provide details)