The imaging instrument at DanMAX has been designed to offer maximum flexibility across a wide spectrum of experimental types and modalities, accommodating a diverse range of samples and sample environments. To facilitate in situ and in operando measurements, the instrument offers a relatively high temporal resolution. Specifically, the DanMAX imaging instrument is engineered to execute a tomography scan in under one second, a feat achieved through a judicious compromise among factors like spatial resolution, dynamic range, signal-to-noise ratio, and temporal resolution.

Experimental Capacity

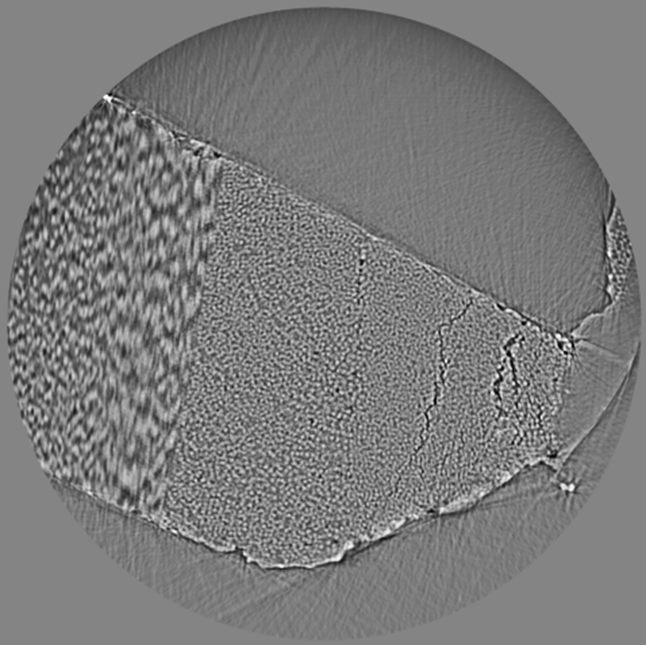

Currently, we support parallel beam projection medium-resolution tomography, encompassing both absorption and phase contrast techniques. As the facility evolves, additional modalities, such as higher-resolution holography and X-ray microscopy, will become available.

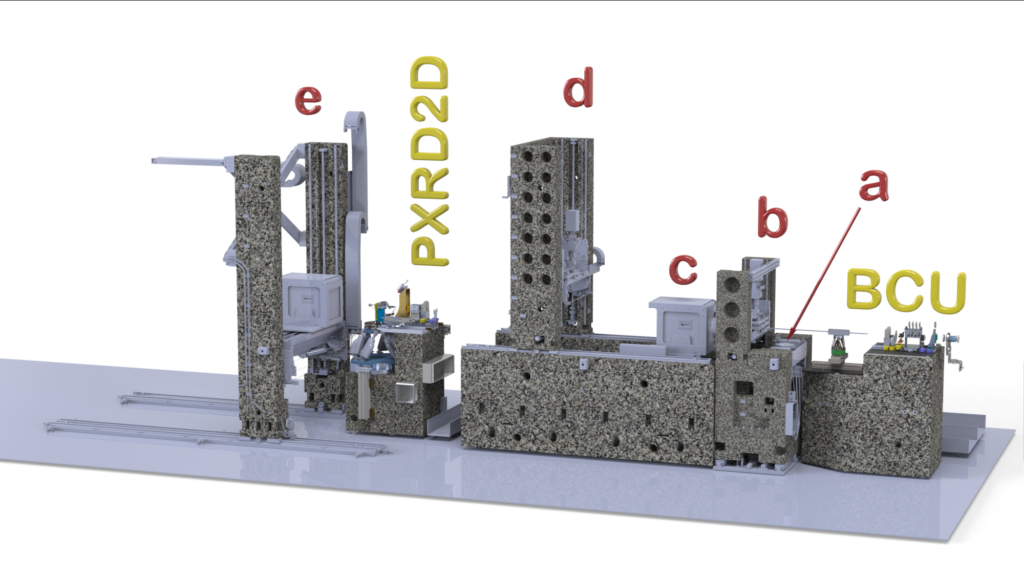

Detection System

The DanMAX’s full field imaging system relies on an indirect X-ray to light conversion optical microscope system. In this setup, X-rays traverse the sample and hit a thin, transparent scintillator screen, thereby generating an image within the visible spectrum. This image is subsequently captured by an sCMOS camera. The microscope adopts a “white beam” geometry, with only the scintillator screen and a right-angle mirror intercepting the X-ray beam. All other optical components, the x10, and x20 objectives, remain outside the beam to shield them from X-ray exposure.

A microscope from Optique Peter is on order and will arrive in 2025. In the meantime, we use a similar microscope kindly lent to us by the TOMCAT beamline at the Swiss Light Source.

The effective pixel size is 550 nm or 275 nm, with an initial field of view limited to the natural beam size at the sample position, using 550 nm pixels, approximately 1.2 x 1.2 mm² or to 1.2 x 0.7 mm² using 275 nm pixels. A larger field of view at the moment can be achieved with raster scanning of a sample and further image stitching.

Camera Specifications

The primary camera utilized in this imaging instrument is the Orca Lightning by Hamamatsu. It has a resolution of 4608 x 2592 pixels (12 Mpx) and has the capability to record up to 120 frames per second at full resolution in a 12 bits dynamic range, or 30 frames per second at full resolution and full 16 bits dynamic range.

For applications where a higher frame rate is desired, the camera can be configured for a lower dynamic range (12 bits) and a smaller region of interest (ROI). For instance, using a 2000×64 pixel ROI, a readout speed of 8000 frames per second can be achieved. The broadband multilayer monochromator plays a pivotal role in ensuring an ample supply of X-ray photons, facilitating high-speed tomography.

Sample Goniometer

DanMAX’s primary sample goniometer is built around the LAB Motion Systems air-bearing rotary stage RT150U, offering an exceptional level of precision with 20 nm radial and axial error motion. A synchronous slave motor, in conjunction with a rotary union for fluid transmission, is employed to drive this goniometer. The rotary union serves a dual purpose: it not only connects the XY alignment stages atop the rotary stage but also provides essential electrical connections for user-specific sample environments, encompassing small motors, trigger signals, and high-voltage supplies. Moreover, two rotary unions offer the flexibility to deliver high-pressure gases, fluids, or create a vacuum environment as required. The maximum supported weight for both samples and sample environments is 5 kg.

Measurement time

A single-volume tomographic scan (~1 mm3) can be recorded in as little as 1 second. Generally, acquisition times for single volumes range between 10 and 300 seconds, depending on exposure, dynamic range, and the objective used. Sample changes are currently manual and take approximately 5 minutes per change.

Larger volumes can be scanned by stitching volumes obtained via local tomography or reconstructing stitched projections. Here the measurement time scales with the desired volume.