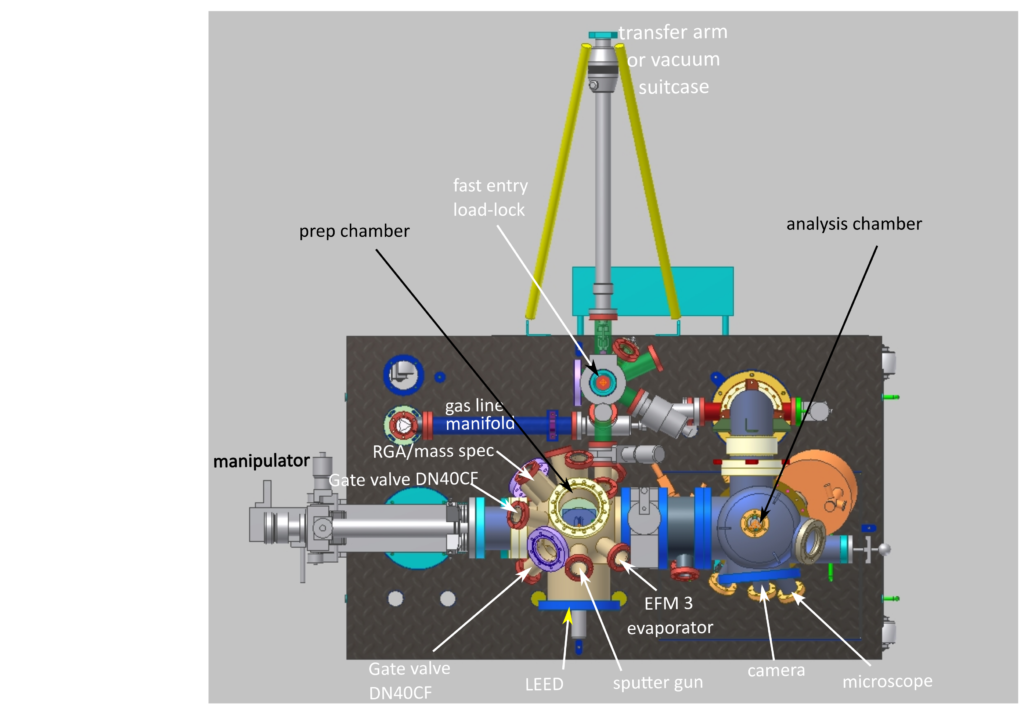

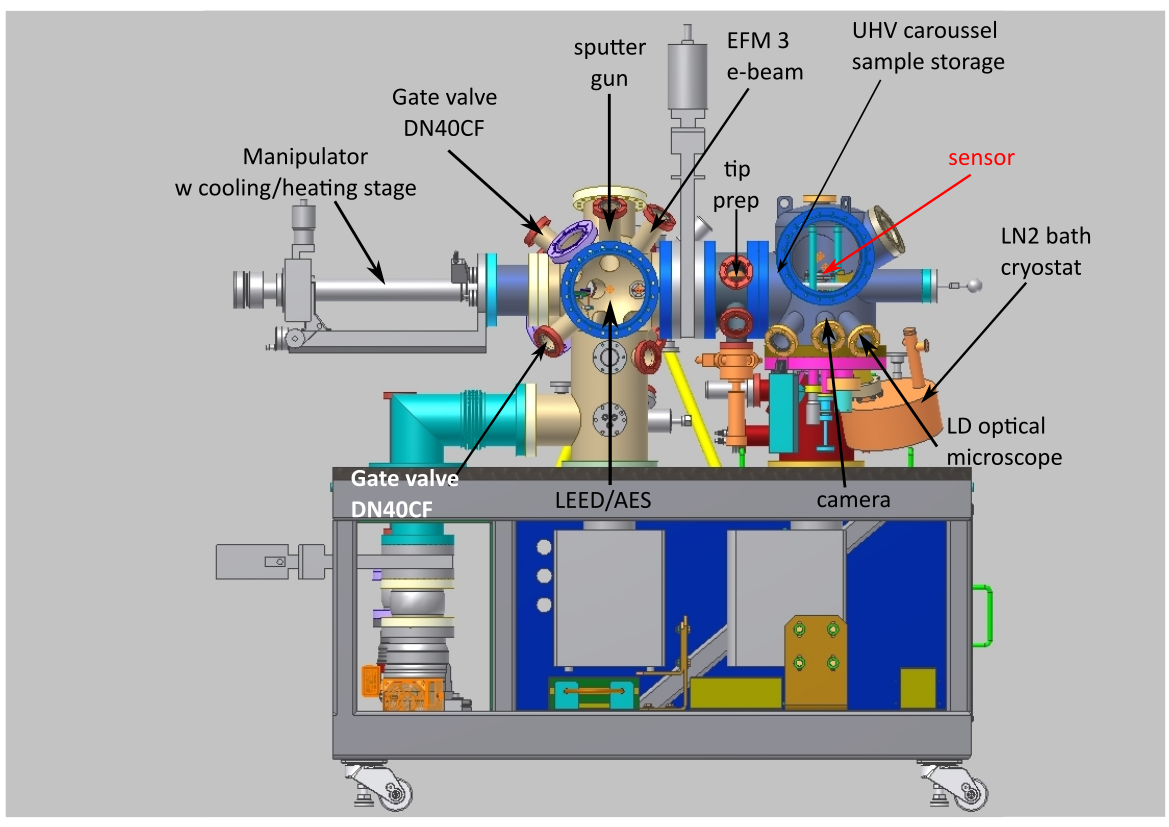

For the preparation of samples in situ a preparation chamber is used, which offers sample cooling, annealing (up to 1200 C), Ar+-sputtering, residual gas spectra analysis / TPD experiments, and characterization with LEED and Auger spectroscopy. A dedicated gas line allows for controllable introduction of ultra-pure gases, and ports are available for mounting own effusion cells / sources, etc…

The microscope is optimized for resolving atomic arrangement of the surfaces, but imaging on a bigger scale is also possible. Our system is UHV-based (ultra-high vacuum, p<1E-10mbar), meaning that no liquid environment around the sample can be allowed. Gas use is restricted and should always be discussed well in advance. AFM measurements may be performed in the non-contact mode only, no “tapping”. We strive for routinely available atomic resolution in the STM (conventional/dynamic), atomic resolution in ncAFM is not guaranteed.

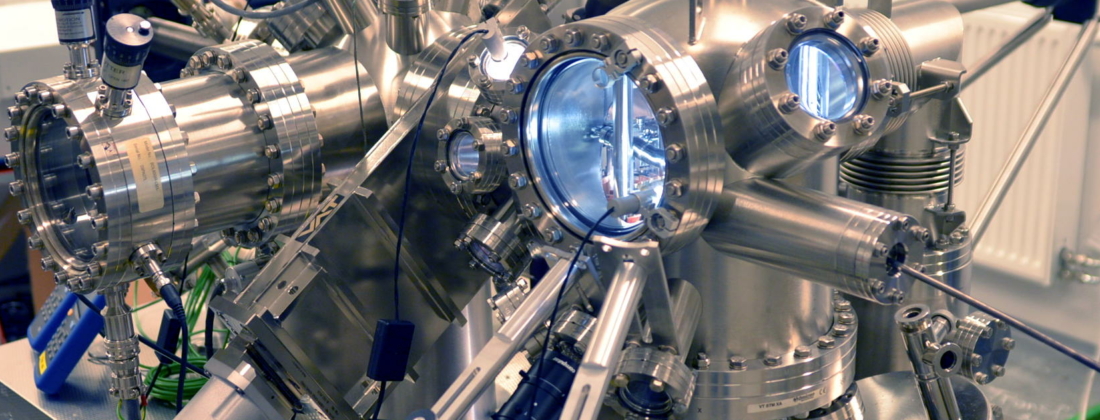

For details of the preparation chamber, the microscope, sampleholders and the vacuum suitcase, see the dedicated pages. The schematics of the experimental set-up is shown in the bottom of this page. The other components of the endstation are:

Loadlock

Fast-entry load-lock (FEL) has a 3-port cassette for temporary in-vacuum storage of samples. For fastest possible pumping, a turbomolecular pump (TMP) is mounted right on the loading chamber. We suggest switching off the FEL turbo when scanning to avoid noise at 1.5 kHz.

FEL can also be pumped via the gas line, just not as efficient. Typical time required to reach the pressure in FEL chamber necessary for introducing the samples from air to UHV (~ 1e-7 mbar) is ~ 1.5 hours with the dedicated turbo and ~ 8 hours via gas line manifold.

Carousel

There is a sample storage carousel in the analysis/STM chamber for storing the samples in the true UHV environment.

Long-distance microscope

For precise positioning of the tip, a long-distance microscope can be mounted on the analysis chamber that allows positioning of the tip with micrometer precision using marks on the surface.

Gas line

Gas line manifold has in normal configuration three outlets for various gases that may be introduced into the prep chamber sequentially or simultaneously via leak valves.

Gas line manifold also allows for differential pumping of equipment mounted on DN40 gate valves (two ports). This allows mounting user sources (evaporators, effusion cells, etc) without venting the chamber.

We have an all-separate entry for Ar sputter gun, disentangled from the rest of gas line which allows for ultra-clean Ar-sputtering.

LEED spectrometer

A 4-grid LEED spectrometer from OCI Microelectronics is mounted on the prep chamber. It allows for low-energy electron diffraction and Auger spectroscopy (with external lock-in amplifier) characterization of the samples.

Quartz microbalance

A movable quartz microbalance that can be placed on the manipulator allows for measuring the flux of atoms or molecules right at the deposition position. See more in sampleholders page.