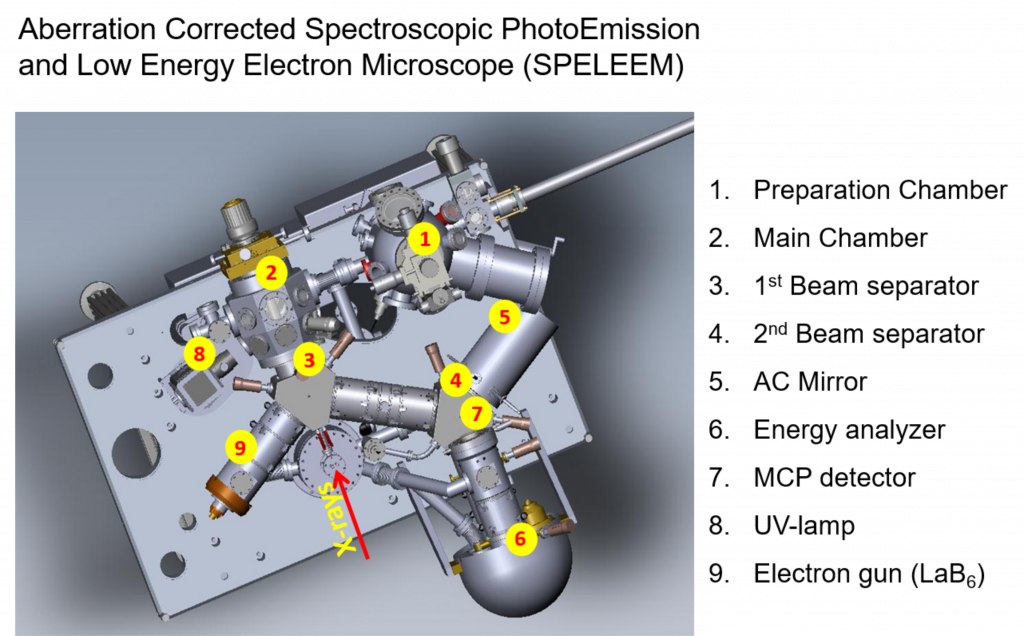

The MAXPEEM endstation is shown in the scheme above, it comprises two main chambers: the preparation chamber, dedicated to sample preparation and treatment facilities, and the main chamber, dedicated to the analysis of the sample surface.

The samples are introduced in a small fast entry chamber connected to the preparation chamber and are then transferred to the preparation or to the main chamber using a transfer arm (top right of the scheme). The main chamber hosts the aberration-corrected SPELEEM microscope (Elmitec GmbH) that consists of nine parts: the illumination optics, two beam separators, the magnetic objective, the intermediate optics, the aberration corrector, the imaging optics, the energy analyzer and the projective system.

The main characteristics of the endstation are summarised in the tables below.

Preparation chamber

| Base pressure | 2⋅10⁻¹⁰ mbar |

| Sample manipulation | 4-axis manipulator with 3 translations (x,y,z) and 1 polar rotation only z is motorized |

| Heating | radiative heating (up to 400 °C) e-beam heating (up to 1500 °C) the temperature is measured with a C-type thermocouple (W5%Re/W26%Re) spot-welded on the Mo ring under the sample, an infrared pyrometer is also available |

| Characterization | RGA (MKS, Microvision 2) LEED (Specs, ErLEED 3000D) |

| Sputter gun | available (Varian, 981-2043) |

| Metal evaporator | available (Focus GmbH, EFM 3) |

| Dosing | two leak valves are mounted on CF40 flanges, one of the leak valves is connected to the gas line composed by two inlets and a dedicated pumping system please, contact the beamline staff in advance if gas usage is planned |

| Available ports | there are additional ports available for user supplied sources: -four CF40 -two CF63 -one CF100 |

| Other | it is possible to load one sample per time in the fast entry chamber that is directly connected to the preparation chamber possibility to attach vacuum suitcase |

Main chamber

| Base pressure | 4⋅10⁻¹¹ mbar |

| Sample manipulation | 3-axis manipulator with 3 translations (x,y,z) plus 1 tilt adjustment (±2°) travel range for x and y: ±5mm |

| Heating | radiative heating (up to 400 °C) e-beam heating (up to 1500 °C) the temperature is measured with a C-type thermocouple (W5%Re/W26%Re) spot-welded on the Mo ring under the sample, an infrared pyrometer is also available |

| Cooling | LN2 |

| UV lightsource | LOT-QuantumDesign GmbH Hg arc lamp |

| Sample storage | capacity: 5 samples |

| Available ports | there are additional ports (CF40) available for user supplied sources |