The endstation offers the following sample environments and auxiliary equipment:

High-Temperature Cell (general purpose)

FTIR spectrometer for simultaneous IRRAS-APXPS

High-Pressure Reactor for offline catalytic tests or sample activation at pressures up to 1 bar

Time-resolved APXPS with pressure or temperature pulses

The endstation placed at the solid-gas branch is designed for Ambient Pressure X-ray Photoelectron Spectroscopy (APXPS) at the solid-gas interfaces at pressures up to 30 mbar. The endstation consists of an analysis chamber equipped with a hemispherical electron energy analyser, onto which ambient pressure experimental cells (AP Cells) can be docked:

Experimental Station

| Sport Size | 60 µm (h) x 25 µm (v) |

| Pressure range for XPS measurements | 2 x 10-10 to ~30 mbar |

| Analyzer | Scienta Hipp-3 with SWIFT acceleration mode |

| Energy range | 260 eV – 2200 eV |

| Ambient Pressure Cells | High-Temperature cell (General Purpose) |

| Additional Equipment and Capabilities | FTIR spectrometer for simultaneous IRRAS-APXPS High-Pressure Reactor for offline catalytic tests at pressures up to 1 bar Time-resolved APXPS with pressure or temperature pulses |

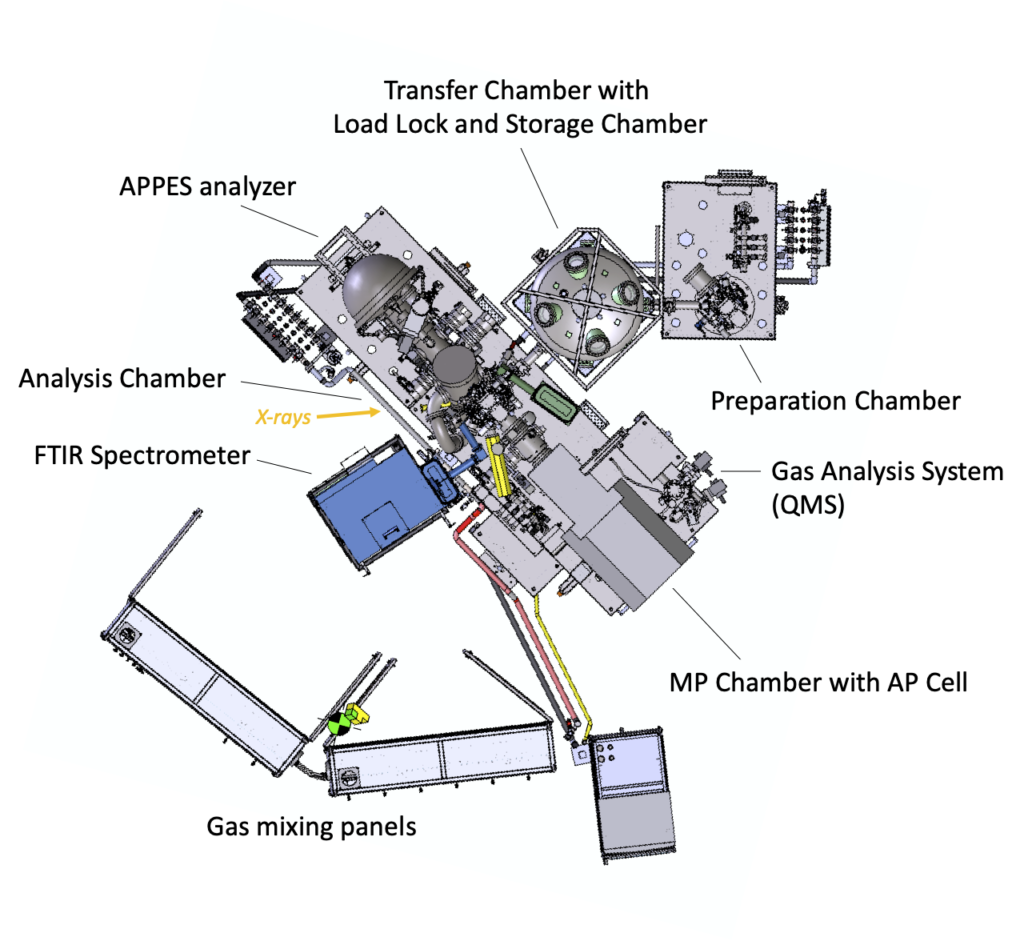

The endstation is a system of UHV vessels connected via a transfer (UFO) chamber. It consists of the Load Lock, Preparation chamber, Analysis Chamber, Storage chamber, and Ambient Pressure Cell chamber. This arrangement allows independent load, storage, preparation, and analysis of up to 12 samples. The ambient pressure (AP) cell is normally stored inside Ambient Pressure Cell chamber. On demand the AP cell can be automatically docked to the front of the analyser where it remains for the duration of the AP experiment.

At the moment, a single High-Temperature cell is available for general users.

In addition to the AP cells, the solid-gas endstation incorporates a FTIR Spectrometer which allows for simultaneous APXPS – Reflection-Absorption IR Spectroscopy measurements. The High-Pressure Reactor connected to the transfer chamber allows for the offline catalytic tests at pressures up to 1 bar.

Sample requirements

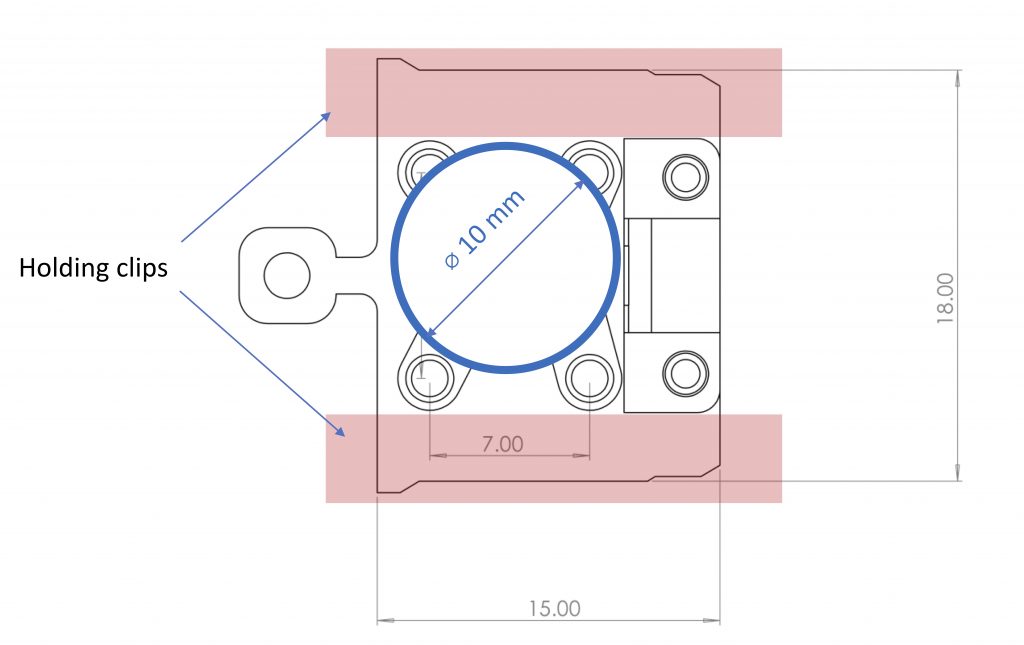

This endstation uses slightly custom “flag” style sample plates. These can have a hole in the plate to allow for direct heating of the sample via an infrared laser and a thermocouple electrical contacts for direct measurement of the sample temperature. Samples are typically mounted on the plates using clips, that can either be attached to the plate by spot welding or screws. Typically, samples are approximately 8 x 8 mm, with a maximum size of 10 x 10 mm (but this is more challenging to mount).

Analyser

| Type | Scienta Hipp-3 analyser capable of recording XPS at pressures up to 50 mbar |

| Energy Resolution | better than 10 meV |

| Spatial resolution | < 10 µm |

| Detector | CCD camera |

| Modes | Transmission (with Swift acceleration) Angular (18 deg acceptance) Spatial |

Analysis in UHV

Use of a UHV manipulator in the analysis chamber is available on request. The “default” experimental configuration just uses the ambient pressure cell for all measurements.

| Base Pressure | 5 x 10-10 mbar |

| Sample manipulation | X, Y, Z, Rot |

UHV Preparation chamber

| Base Pressure | 2 x 10-10 mbar |

| Sample manipulation | X, Y, Z, Rot |

| LEED | OCI BDL800IR-3GR |

| Sputter Gun | Prevac IS 40C1 |

| Heating Type | E-beam (up to 900 C with stainless steel sample holders) heater operated by PID controller |

| Cooling | Water |

| Deposition Sources | Focus EFM3 (by request) User-defined. Available ports CF 40, CF 63 |

| QCM Balance | Prevac TMC13 / TM14 |

| RGA | MKS Microvision 2 Up to 300 amu |

Load Lock and Storage Chamber

| Base Pressure | 2 x 10-10 mbar (Storage Chamber) 2 x 10-8 mbar (Load Lock; after bakeout) |

| Sample Holder | Omicron flag style |

| Sample size | up to 8×8 mm2 |

| Storage | 6 inside Load Lock + 6 inside Storage Chamber |

| Transfer time | ~ 1 min |