A number of LDM sample delivery systems are available at MAX IV (including a molecular jet/cluster source, liquid microjets, magnetron based source for metal particle beams, an aerodynamic lens sample delivery system) and more are under development (liquid flat jet setup – monitor this page for more details).

Molecular jet source / Cluster source

This sample delivery system delivers a continuous beam of atoms/molecules/clusters. Since the source is shared with other LDM beamlines, it is essential to discuss the availability and status with the LDM team or beamline staff well in advance. Note: an online booking procedure is planned for the future (information regarding this will be provided in due course).

| Description | Adiabatic expansion source with cylindrical sample reservoir. Reservoir heating and nozzle heating possible. |

| Manipulator | Z-travel 400 mm, XY ±12.5 mm |

| Nozzles | Cu nozzles, typical opening diameter for a conical nozzle 150 µm (50-100 µm diameters flat nozzles are feasible) |

| Temperature | Sample heating up to 150 °C possible |

| Samples | Gaseous and Aqueous (for evaporation). All samples must be declared; aggressive, flammable or toxic samples may be denied |

| Seeding | Possible: Via co-expansion |

| Vacuum | Ancillary chamber with 2 x ATH 500M (500 l/s) turbo pumps and ACP40 GCV forevacuum pump. Manipulator with sample rod is mounted, and an additional liquid nitrogen cold trap is planned |

| Operational mode | Continuous beam |

| Differential pumping | Modular differential pumping setup with double skimmer (Cu skimmers, 50 µm – 1 cm in diameter) arrangement and 3 x 67 l/s turbo pumps |

| Compatible beamlines / end stations | FlexPES, FinEstBeAMS, ICE |

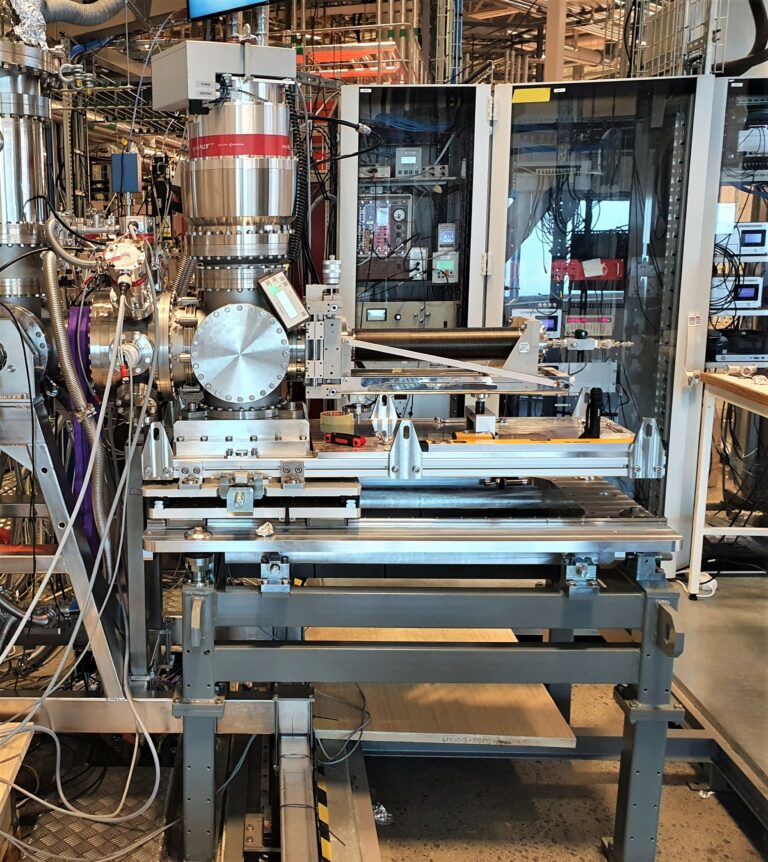

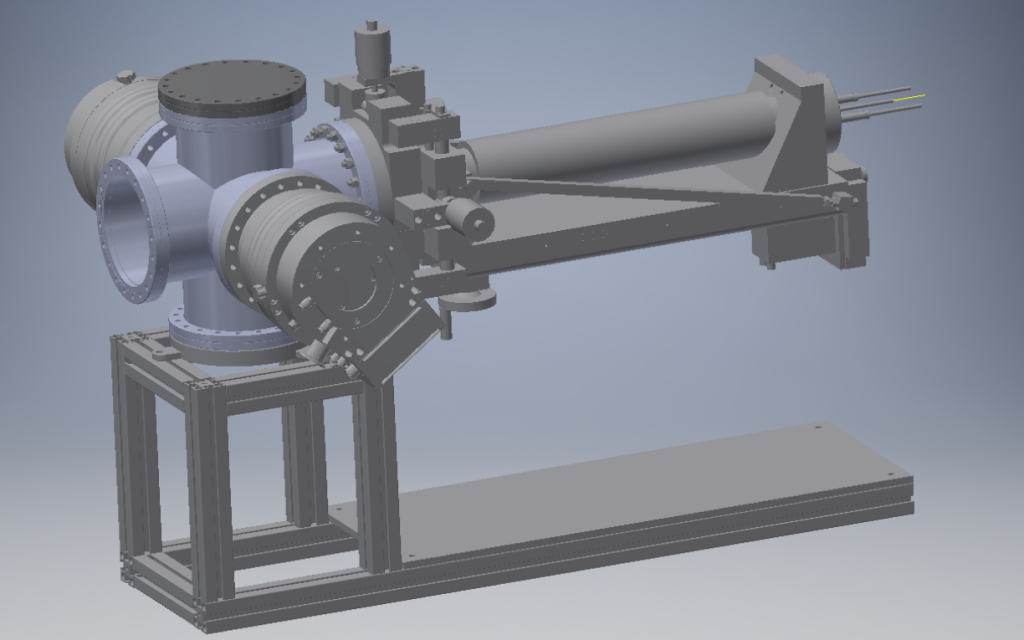

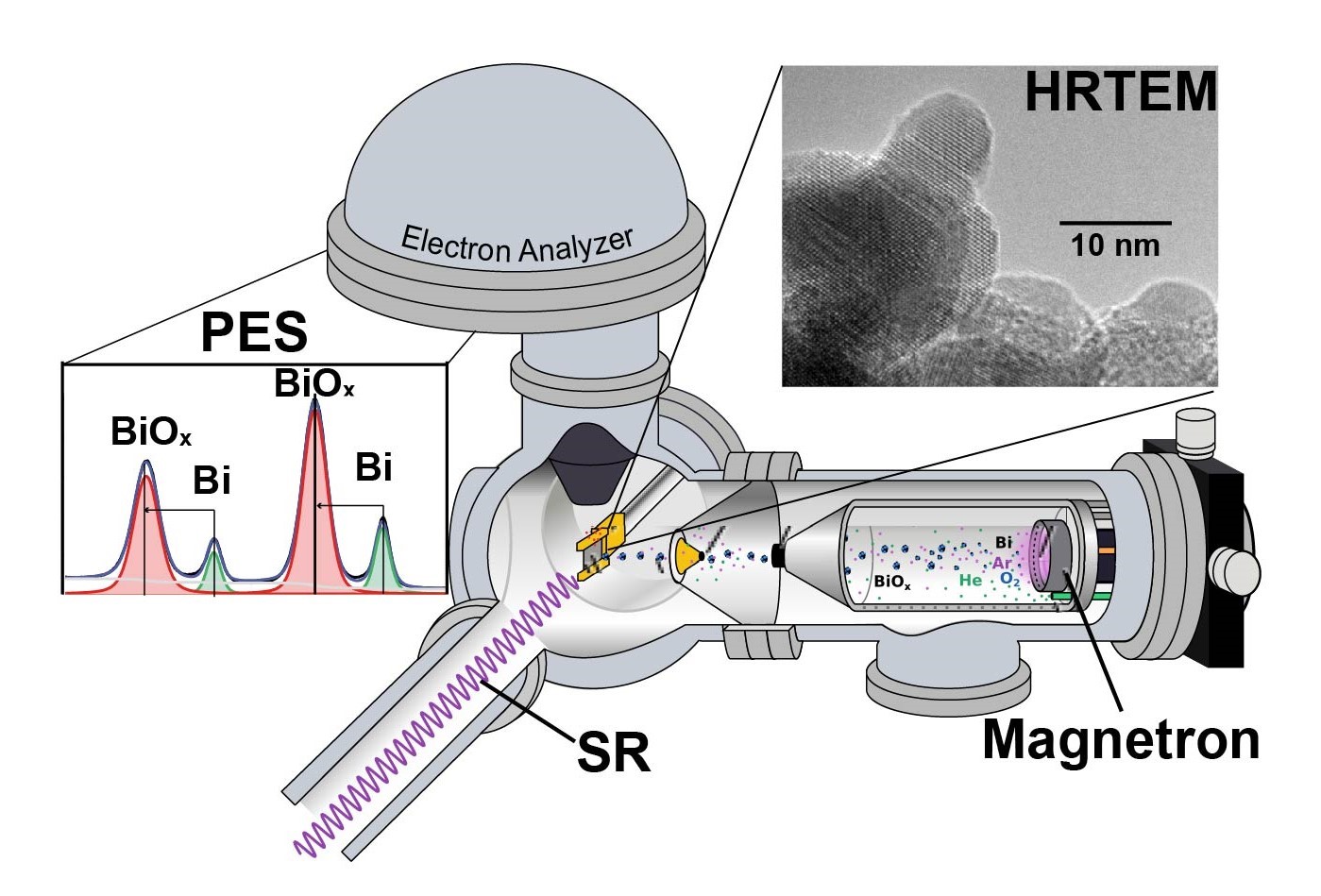

Magnetron cluster source

Metal-cluster source based on vapour aggregation

A cluster source based on vapour aggregation and magnetron sputtering has been made available for the general-user operation. The source can create a beam of free clusters out of metals with high sputtering rate, such as Pb, Sn, Bi, Cu, Ag, Au, and some others. Additionally, the source can produce free clusters containing metal oxides and nitrides. The clusters can be studied in a beam and deposited on a substrate by XPS and XAS.

Liquid microjet source

FlexPES

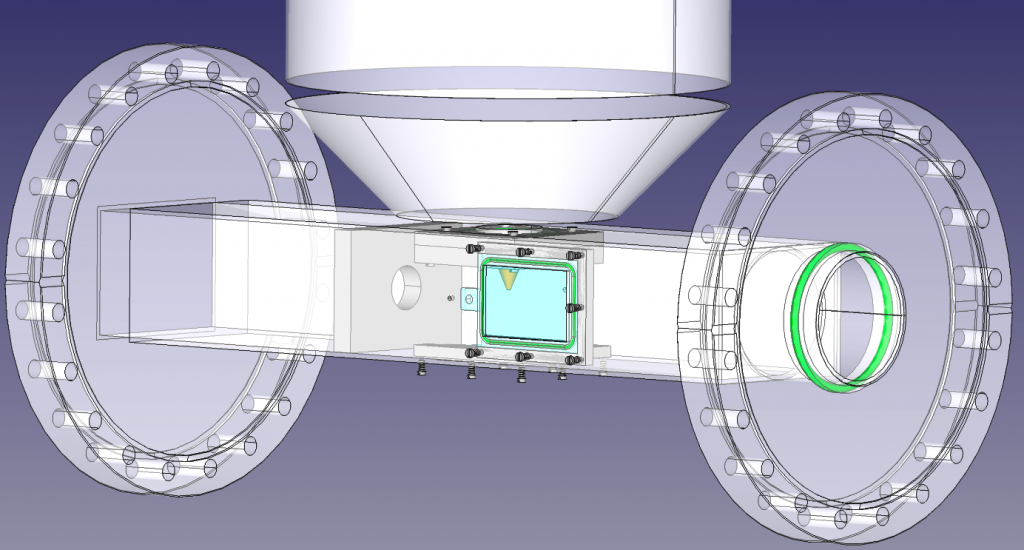

Sketch of new differential pumping insert for the liquid jet experiment at FlexPES:

| Manipulator | Z-travel 400 mm, XY ±12.5 mm |

| Nozzles | Quartz glass nozzles, typical opening diameter 20-25 µm (10-50 µm diameters are feasible). 30-40 µm available. |

| Liquid delivery | HPLC pump, stainless steel cylinder, typical flows 0.5 - 1 ml/min; PEEK tubing and filters, DEGASi PLUS Semi-Prep 4-ch 925μl degasser. |

| Temperature | Jacket with flowing liquid surrounding sample delivery tube for cooling/heating. Polyscience SD07R-20 chiller. |

| Samples | Aqueous solutions in particular, but other solvents possible (pending approval by MAX IV chemical safety group). Samples must be conductive to some degree to allow electron spectroscopy; ion concentration needed depends on species. All samples must be declared; aggressive, flammable or toxic samples may be denied. |

| Disposal | Sample caught in liquid nitrogen trap for subsequent disposal; no recycling possible |

| Vacuum | Ancillary chamber with 2x HiPace1500C (1450 l/s) turbo pumps, where manipulator with sample rod is mounted, and additional liquid nitrogen cold trap. |

| Compatible beamlines / end stations | FlexPES, FinEstBeAMS, ... |

Veritas

| Manipulator | Z-travel 400 mm, XY ±12.5 mm |

| Nozzles | Quartz glass nozzles, typical opening diameter 20-25 µm (10-50 µm diameters are feasible). 30-40 µm available. |

| Liquid delivery | Typical flows: 0.6 ml/min flow with 30um diameter nozzle (pure water). In commissioning; PEEK tubing and filters. DEGASi PLUS Semi-Prep 4-ch 925μl degasser. |

| Temperature | Polyscience SD07R-20 chiller. |

| Samples | other solvents possible (pending approval by MAX IV chemical safety group). Samples must be conductive to some degree to allow electron spectroscopy; ion concentration needed depends on species. All samples must be declared; aggressive, flammable or toxic samples may be denied. |

| Disposal | Sample caught in liquid nitrogen trap for subsequent disposal; recycling option available in the future |

| Vacuum | Main chamber: Pfeiffer Hipace300 (260l/s) and/or Pfeiffer Hipace700 (658l/s). Forevacuum pump: Dry multistage roots pump Pfeiffer ACP 28 or 40. Differential pumping chamber: Pfeiffer Hipace80 (67l/s), Forevacuum pump: Dry multistage roots pump Pfeiffer ACP 28 or 40. |

| Compatible beamlines/end stations | Veritas, FinEstBeAMS... |

HIPPIE

| Manipulator | motorized (for jet and catcher) |

| Nozzles | Quartz glass nozzles, typical opening diameter 15 and 25 µm. 30-40 µm available. |

| Liquid delivery | HPLC pump, stainless steel cylinder, typical flow rate will be updated soon; PEEK tubing and filters, Capillary mixing of 2 liquids is available. Liquids can be degassed in a separated vacuum chamber pumped by a forevaccum pump. |

| Temperature | Jet manipulator has heating/cooling jacket. The catcher can also be heated and cooled. |

| Samples | Use of solvents depends upon approval by MAX IV chemical safety group. Samples must be conductive to some degree to allow electron spectroscopy; ion concentration needed depends on species. All samples must be declared; aggressive, flammable or toxic samples may be denied. |

| Disposal | Catcher, which must be emptied periodically |

| Vacuum | Large volume vacuum vessel with two manipulators. Top manipulator holds the microjet; bottom manipulator holds the catcher (300 ml). Cell access is done via 300 mm front "door" (load-lock style). Vessel is equipped with halogen lamps for homogenous environment heating. Base pressure: 1e-5 mbar (not bakeable) Pressure range: 1e-5 mbar – 30 mbar. Jet operates at equilibrium liquid pressure (24 mbar for water at RT). |

| Compatible beamlines/end stations | HIPPIE |

Aerodynamic Lens Sample Delivery System

| Description of aerodynamic lens system: | Aerodynamic particle sampling lens for PM 1 (Aerodyne Research Inc.) |

| Aerosol sampling inlet transmission range | 40nm - 1um |

| Critical orifice | 100um |

| Manipulator | Z-travel 400 mm, XY ±12.5 mm |

| Samples | Commissioned with salt aerosols and engineered nanoparticles. Please contact the beamline/LDM staff to discuss sample generation possibilities. |

| Operating pressure | ~1mbar |

| Vacuum | Ancillary chamber with 1 x ATH 2303M (2150 l/s) turbo pump |

| Operational mode | Continuous |

| Differential pumping | Modular differential pumping setup. Single/double skimmer arrangement possible (Cu skimmers, 1mm orifice diameter) and 3 x HiPace80 (67 l/s) turbo pumps. |

| Accessories | Constant Output Atomizer and Diffusion Dryer (non-cobalt) from TSI Inc. |

| Compatible beamlines / end stations | FinEstBeAMS (commissioning planned for HIPPIE, FlexPES). |

| Status | Available to general users!! In advance of submitting a proposal, please consult with the LDM team or the FinEstBeAMS BL manager concerning potential samples. All samples must be declared; Aggressive, flammable or toxic samples may be denied. |