To be able to develop more sustainable and durable materials, global tool steel manufacturer Uddeholm is using synchrotron X-rays to study new possible ways to optimise the hardening treatments of advanced tool alloys.

How can industrial tools perform better and last longer? A crucial step is to make the tool’s metal surface more resistant to corrosion.

Together with a team of researchers from KTH (the Royal Institute of Technology in Stockholm) and Lund University, tool steel manufacturer Uddeholms AB is currently investigating how the steel’s surface is affected by exposure to different corrosive environments including ambient air. The experiment also investigates how the corrosion resistance could be improved by heat treatments during the processing.

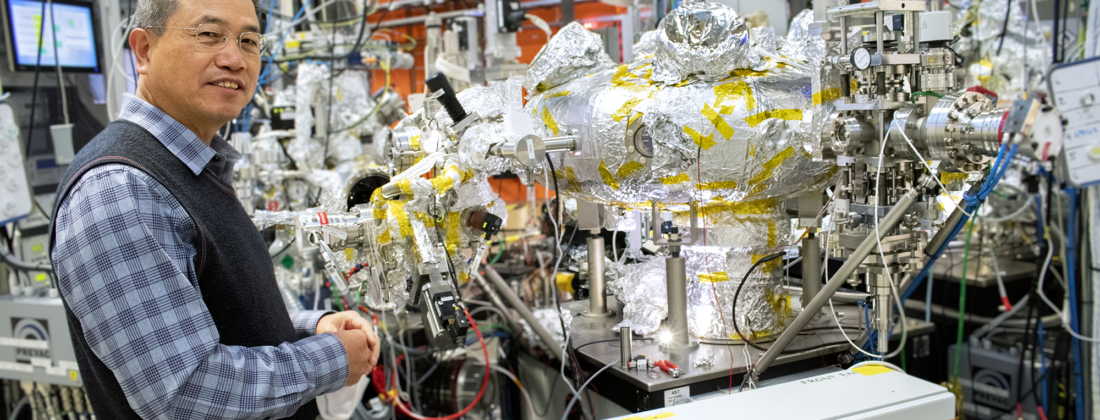

Using synchrotron-based X-ray photoelectron spectroscopy (XPS) techniques such as ambient-pressure photoelectron spectroscopy (APXPS), hard X-ray photoelectron emission spectroscopy (HAXPES), and hard X-ray photoelectron emission microscopy (HAXPEEM), the research team is studying the nature of the passive films that form spontaneously on metallic surfaces. These thin passive films play a decisive role in the material’s corrosion resistance.

“At this stage, we are analysing the surface layer to get information about the chemical composition and electronic state of the passive films: the thickness, composition, and the effects of heating and cooling on the microstructure”, explains Jinshan Pan, professor at KTH, who is supervising the research team.

“So far, we have done the first test XPS measurement and already obtained some interesting results.”

“A roadmap to the future”

The HAXPES and HAXPEEM measurements will be done at the Petra III beamlines at the synchrotron DESY in Germany, while the APXPS measurement will be done at the HIPPIE beamline at MAX IV in Lund.

“Depending on what we discover, the data might give us new ideas and insights into how we can develop superior materials and better solutions for industrial applications. It will be an important part of our company’s roadmap to the future”, says Dr. Krishnan Hariramabadran Anantha, R&D engineer at Uddeholms AB.

The synchrotron experiment is an important part of a pilot research project supported by Vinnova.

Are you also interested in doing industrial research at MAX IV? Don’t hesitate to contact our Industrial Relations Office. Feel free to be inspired by what other industrial companies have researched – have a look at our cases.

Related links