People consume goods daily without realising the journey those products have been through before being displayed on store shelves. Everything involved in the production is a result of thorough R&D, even the eye-catching package of the products has gone through a substantial evolution. To this day, researchers are working on taking the packaging to the next level.

While millions of people around the world reach for the dairy products on the shelves of their local stores, Per Johansson, Technology specialist at Tetra Pak, a world-leading food processing and packaging solutions company that has gained international fame as the most innovative in the field, works on improving the packaging process at the company.

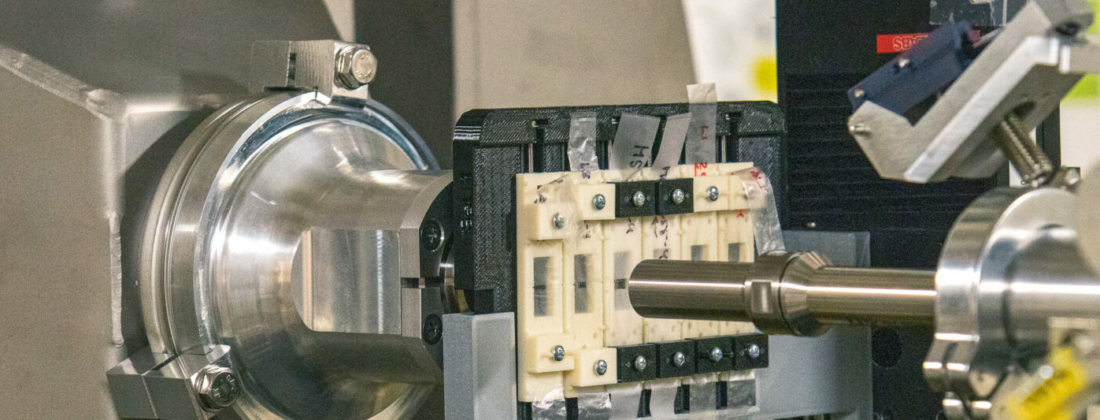

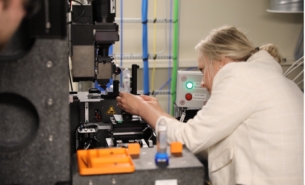

By using the CoSAXS beamline at MAX IV to study the morphology of the polymer used on the package, Per studies how manufacturing processes and the properties of the polymer influence performances related to production quality, ability to pack various food products, and production speed.

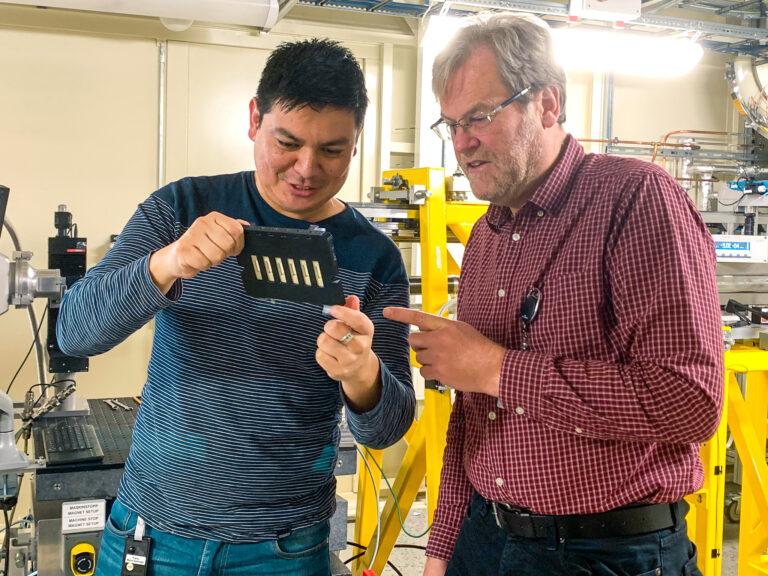

The project is a collaboration between Tetra Pak and MAX IV with Tomás Plivelic, CoSAXS Beamline Manager and Ann Terry, CoSAXS Beamline Scientist & Group Manager as partners from MAX IV. While discussing the potential areas for collaboration an experiment focusing on the morphology of polymer became a matter of interest. A teaser of the research was conducted at the synchrotron in Brazil. Although only one sample was tested with a few measurement points, the test experiment was successful as it proved to be useful for further research.

SAXS technique applied by the newly launched CoSAXS beamline can provide information on the polymer nanostructure. Studying the data gives a better explanation of the structure of different polymers, in particular packing and preferential alignment of molecular chains. By understanding the structure at the nanoscale, it will be possible to observe how the polymer behaves during the sealing and production process.

The measurement gives an image of crystallinity and orientation of the polymer which helps in detecting the change caused by the sealing process. The experiment can support manufacturers in their decision-making regarding what type of production technique should be adopted or what kind of polymer should be used.

In short, by studying the structure of different polymers, we provide information on how the sealing process interacts with the material. This will help to adapt the sealing process for different packaging materials and food types.

Interested in doing industrial research at MAX IV but don’t know how? Feel free to contact our Industrial Relations Office. In the meantime, be inspired by what other industrial users have researched – have a look at our cases.