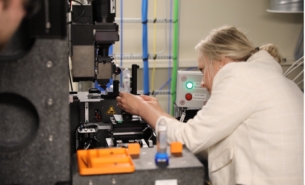

The newest research station at MAX IV, ForMAX, has hosted its first industry experiment: A ground-breaking study on fibre-based sustainable food packaging, performed by Tetra Pak in collaboration with Chalmers University of Technology.

Today, global food packaging and processing company Tetra Pak announces the commencement of new research using advanced X-ray scattering imaging techniques at ForMAX, the newest beamline at MAX IV laboratory. The study aims to uncover fresh insights into the nanostructure of fibre materials, with the first application to optimise the composition of materials used for paper straws.

In the strive to meet the increased global market demand for more sustainable packaging solutions, new materials based on paper can bring novel opportunities. Yet, these new, paper-based materials must remain food safe, recyclable, and durable against liquids and humidity while meeting the increased sustainability demands.

These are some of the challenges that Tetra Pak is collaborating with MAX IV to address using the laboratory’s advanced research techniques.

“Our first experiment, which starts with paper straws, provides additional analysis capabilities into how paper straw material responds to changes in the environment in real-time, as well as how the straw interacts with different types of liquids under stringent conditions. These new insights and knowledge will be applied to developing the paper straws of the future in our virtual modelling tools, helping us to improve their functionality”, explains Eskil Andreasson, Technology Specialist, Virtual Modelling at Tetra Pak.

“Fresh insights into plant-based materials as a basis for future innovations”

Eva Gustavsson, Vice President, Materials & Package at Tetra Pak, says:

“A fundamental understanding of the structure and properties of materials is crucial as we work towards developing the package of the future. Our ambition is to provide the world’s most sustainable food package, and experiments at ForMAX will support us in this mission.”

“The package of the future needs to be fully recyclable and have a low environmental impact. Using renewable materials and increasing the use of fibre-based materials within packages will be vital. With this research, Tetra Pak is helping to uncover fresh insights into plant-based materials as a basis for future innovations.”

A milestone for academia and industry

The ForMAX beamline opened for experiments in autumn 2022. It is specially designed for advanced studies on wood-based materials. The beamline is an initiative where several market-leading industry companies, mainly from the paper and pulp industry and academia, have joined forces. The Knut and Alice Wallenberg Foundation has funded the construction work, while the industry funds the operational costs through Treesearch, a national collaborative platform for academic and industrial research in new materials from the forest.

“This experiment is a milestone for academia and industry. The research station is the first of its kind and will facilitate fundamental and applied industrial research on how new, sustainable materials can be used. We are proud to support Tetra Pak in developing sustainable packaging materials for the future,” says Kim Nygård, Manager, ForMAX beamline, MAX IV.

Read the full press release here.

Read more about ForMAX and watch the ForMAX introduction video here.

Visit Treesearch or Knut and Alice Wallenberg Foundation.

Are you a company interested in doing research at ForMAX?

Contact the MAX IV Industry Office here.