Waste management is an important topic in Sweden. The technology involved in the processing of the waste is top-notch which means the materials used to produce such machinery are wear-resistant and need less maintenance. Nevertheless, experts do not miss opportunities to improve the quality of materials, especially metals.

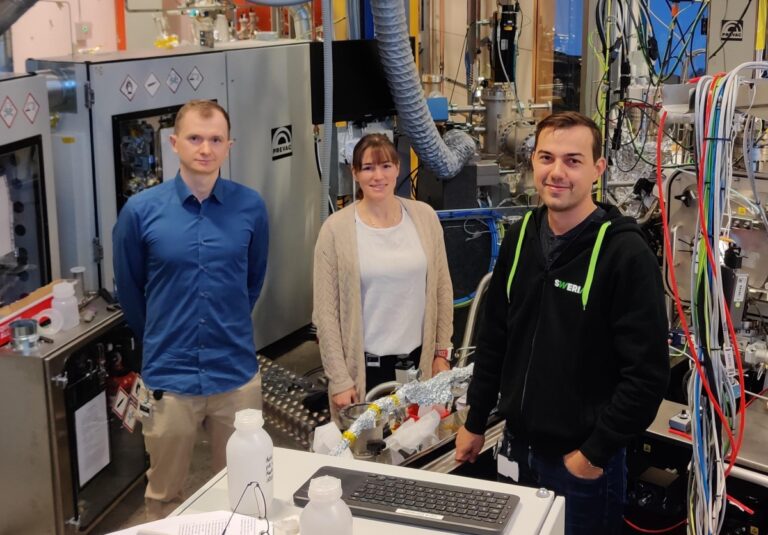

SSAB has been providing the industry with high-quality metal plates and sheets for years, but the company is interested in further development of the product it offers. In collaboration with Swedish Research Institute for Mining, Metallurgy and Materials – Swerim, SSAB explored the stability and chemical composition of surface oxides on wear-resistant steels at the HIPPIE beamline of MAX IV.

This study aims at gathering data on how a new category of steel is more durable but at the same time equally wear-resistant. This kind of product is very important for the waste management industry.

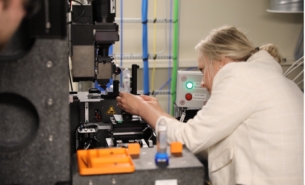

During the experiment, two kinds of high-strength steels were used as samples. Both samples were dipped in the electrolyte solution simulating the working environment of waste management equipment. The anodic potential was applied to the samples to accelerate the corrosion initiation. The samples were then slowly pulled out of the solution to preserve the very thin film of electrolyte on the sample surface. The Ambient Pressure X-ray Photoelectron Spectroscopy (AP-XPS) was applied to observe chemical changes at the steel surface in contact with electrolyte film and follow the corrosion attack mechanism in-situ.

The outcome of this study will help in understanding the effect of the chromium content on the corrosion of high-strength steels and thus, come up with new solutions that will prevent or reduce corrosion failure. This way, the company can produce steel that is more durable and in turn less maintenance for the customer.

The project is financially supported by the Swedish innovation agency, Vinnova. To see the other similar projects sponsored by Vinnova, click here.