Arevo, a company known for producing environmentally friendly solutions for improved plant establishment and growth, has performed its first experiment at MAX IV. The research is focused on developing a new line of biostimulant products with a unique nutrient release profile, ensuring beneficial long-term effects for both plants and soils.

Arevo produces plant biostimulants to ensure an environmentally friendly way of increasing plant growth, while keeping soils healthy and reducing nutrient losses to a minimum. This is done by addressing the sustainability goals articulated in the European Commission’s “From Farm to Fork” strategy to reduce input of fertilizers and nutrient losses until 2030.

The biostimulants are based on organic nitrogen compounds such as amino acids. This technology was first discovered through professor Torgny Näsholm’s revolutionary research in the field of plant nutrition.

Reducing the environmental impact

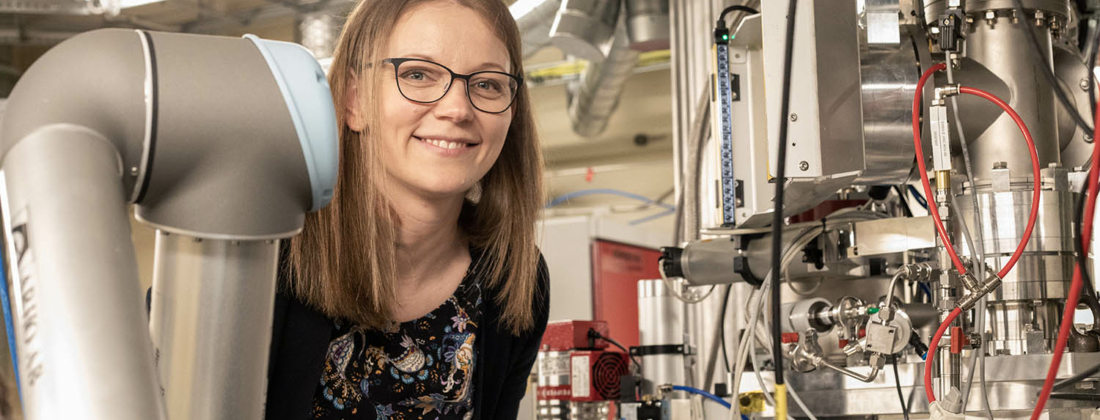

Regina Gratz, business and product development manager at Arevo, highlights that small amounts of the new biostimulants will have a significant effect on growth and quality of produced seedlings in forest nurseries, as well as on diverse crops in agriculture.

The efficient capture of nitrogen and phosphorus will allow for the industry to produce vigorous plants – with a minimum of environmental impact.

On this topic, Arevo will conduct a series of experiments at MAX IV. Together with scientists from Umeå University the first experiment has now taken place.

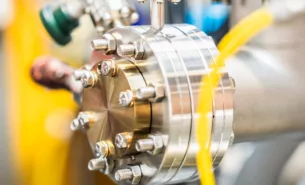

Using X-ray absorption spectroscopy at the BALDER beamline, they studied the local structure of elements added to the organic nitrogen source. Through these experiments they aim to observe the amount of light absorbed by each atom and thereby understand its chemical environment.

“These types of Vinnova funded research projects give businesses the opportunity to be introduced to synchrotron-based techniques”, says Nils Skoglund, associate professor at the Department of Applied Physics and Electronics at Umeå University, in an interview with umu.se.

“They are sometimes necessary for material characterization, when the laboratory experiments including our own powder diffraction at TEC-lab and the excellent capacity at our Vibrational Spectroscopy Core Facility (VISP) here at Umeå University are not enough.”

Interested in doing industrial research at MAX IV but don’t know how? Feel free to contact our Industrial Relations Office. In the meantime, be inspired by what other industrial users have researched – have a look at our cases.